Do you know how to remedy the fence if it is rusted? Th […]

Do you know how to remedy the fence if it is rusted? The technical personnel of the fence manufacturer will explain it to you. I hope it can help you.

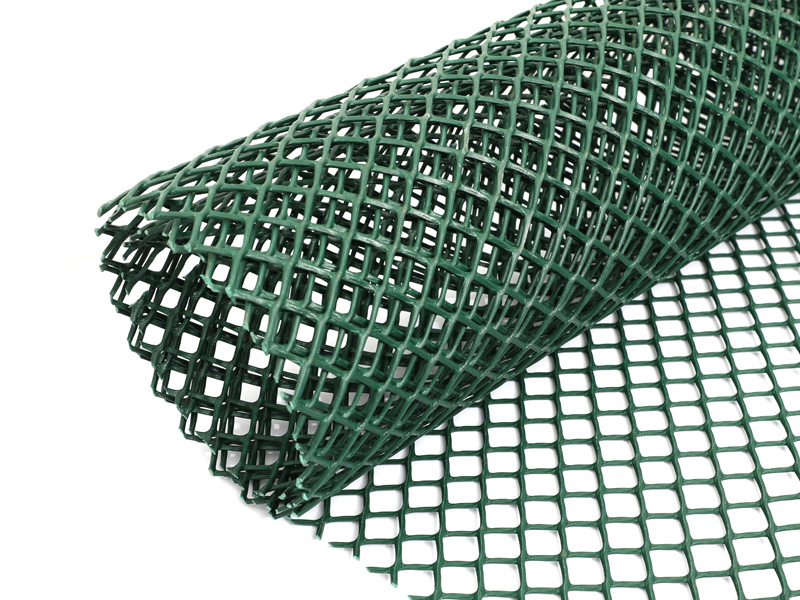

The main material of the fence mesh is welded with low-carbon steel wire. Iron is an oxide. It will rust when exposed to water molecules in the air. The rusty iron will become fragile and loose for a long time. At present, the anti-rust treatment methods on the surface of the fence net include cold (electric) galvanizing, hot-dip galvanizing, plastic dipping, plastic spraying, plastic spraying, baking paint and other processes. At present, the fence mainly adopts the four anti-rust processes of cold galvanizing, hot galvanizing, spraying and dipping. As soon as the zinc layer comes off, no anti-rust effect will be achieved.

After many customers have purchased the fence, after a year or two, the surface of the fence will look dirty for a long time due to the dust on the road surface. The cleaning of the fence should be based on the requirements of the surface treatment of the fence. If the surface is galvanized, it is not recommended to clean it with water, because the galvanizing treatment infiltrates a layer of zinc into the iron wire, and it will be used in a wet place for a long time. The zinc layer peeled off.

Therefore, fence manufacturers are not recommended to use water cleaning. It can be cleaned by high-pressure air blowing or vacuum cleaner. Pay more attention to the shedding of the zinc layer. If there is a shedding of the zinc layer, spray some silver paint for maintenance. If the surface is dipped or sprayed, high-pressure water spraying can be used for cleaning. Plastic dipping or spraying is a kind of plastic coating treatment. The main raw materials are polyvinyl chloride and polyethylene, which is to wrap a layer of plastic on the iron wire to cut off the fence and the air from oxidation.

The process surface of the fence net is smooth, and the dust on it can be removed by high-pressure water spraying. When spraying and dipping plastics are processed, there will be working point processing. The plastic coating of these working points is uneven. Customers pay more attention to spraying and maintenance of the working point.

WhatsApp:+8613626888261

WhatsApp:+8613626888261