In the maintenance of traditional drainage systems, it […]

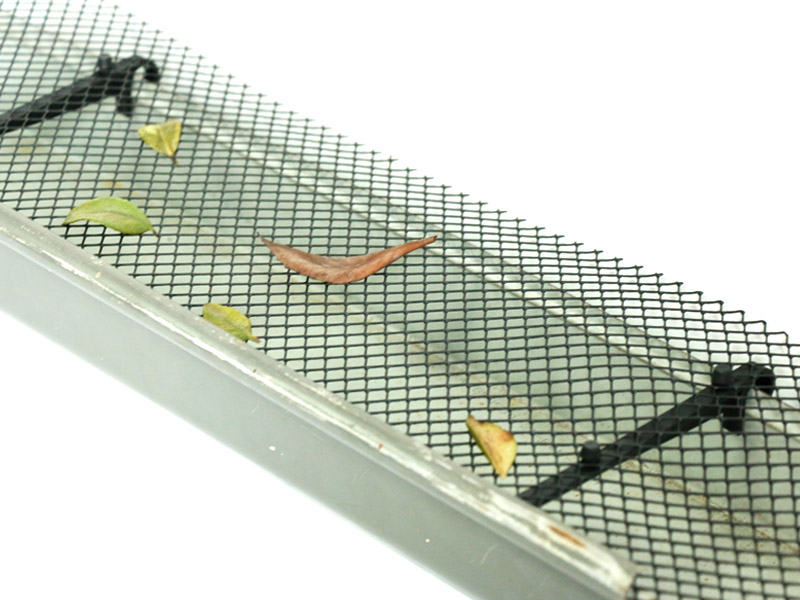

In the maintenance of traditional drainage systems, it is often a challenge to choose the right protective materials and install them accurately in the face of drainage ditches of various shapes. The emergence of gutter nets undoubtedly provides an elegant solution to this problem. The high-density polyethylene (HDPE) material used is not only wear-resistant and corrosion-resistant, but also easily adapts to various complex drainage ditch environments with its excellent flexibility. What is even more surprising is that during the installation process, users do not need complex tools or professional skills. With just a pair of ordinary scissors, they can cut the appropriate length according to actual needs and achieve accurate installation.

So, using such a simple tool for cutting, will the edge of the gutter net have burrs or unevenness as people worry? The answer is no. The design team of the gutter net knows that while pursuing efficiency and convenience, the quality and details of the product cannot be ignored. Therefore, they have carefully considered and optimized the material selection and production process.

First of all, from the perspective of the material itself, high-density polyethylene has excellent plasticity and toughness, which enables the gutter net to maintain good shape stability and edge flatness when subjected to external forces. Even when using ordinary scissors for cutting, due to this characteristic of the material, it is not easy to have obvious burrs or cracks on the edge.

Secondly, the production process of the gutter net is also commendable. During the production process, the manufacturer uses advanced mold forming technology and precise cutting technology to ensure that each piece of gutter net undergoes strict quality inspection before leaving the factory. This persistence and pursuit of quality enables the gutter net to show a more perfect edge effect during the cutting process.

In actual operation, users only need to follow the instructions in the product manual, select suitable scissors, and cut along the predetermined lines. During the cutting process, due to the material and process advantages of the gutter net, the edge will present a natural and smooth texture without the need for additional grinding or processing. This perfect combination of convenience and aesthetics undoubtedly brings great convenience to the installation and maintenance of the drainage system.

In addition, this feature of the gutter net is also reflected in the convenience of its maintenance and replacement. When the drainage system needs to be partially adjusted or upgraded, users only need to use ordinary tools to easily complete the cutting and replacement of the gutter net, greatly reducing the maintenance cost and time cost.

WhatsApp:+8613626888261

WhatsApp:+8613626888261