In the industrial field, especially in the process of h […]

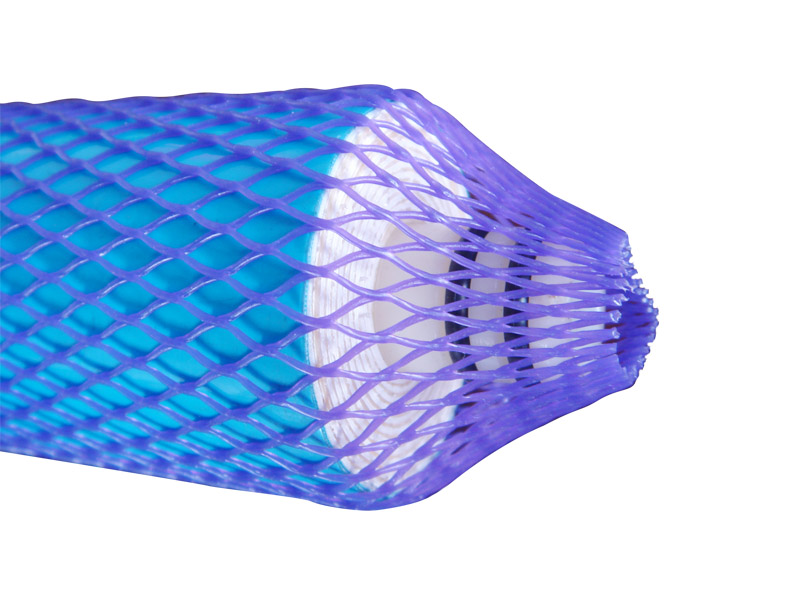

In the industrial field, especially in the process of handling toxic, harmful or corrosive substances, the safety and reliability of protective equipment are crucial. As one of the best, the rigid tubular mesh protective tube has a unique internal mesh structure design that provides it with excellent protection performance. Today, we will explore the mystery of this design together.

The internal mesh structure of the rigid tubular mesh protective tube is not a simple mesh superposition, but the result of careful design and precision manufacturing. The structure is woven by high-strength steel wire through a special process to form a mesh skeleton with strong support and impact dispersion. This design not only ensures the durability of the protective tube, but also effectively disperses external impact forces and reduces damage to internal filters or equipment.

In the design of the mesh structure, engineers considered a variety of factors. The first is the choice of materials. High-strength steel wire has excellent compression, impact and wear resistance, which can ensure that the protective tube can remain stable in various harsh environments. The second is the density and weaving method of the mesh structure, which will directly affect the strength and durability of the protective tube. After many tests and optimizations, engineers finally determined the optimal mesh structure parameters.

In addition to providing physical protection, the internal mesh structure of the rigid tubular mesh protective tube also has other functions. For example, it can effectively prevent the leakage and contamination of liquids, gases and solid particles, and ensure the normal operation of filter elements and other equipment. In addition, the mesh structure can also reduce the resistance of the fluid in the pipeline and improve the efficiency of fluid transmission.

The internal mesh structure of the rigid tubular mesh protective tube also fully considers the convenience of maintenance and replacement during the design process. Because the mesh structure has a certain elasticity, it can be easily disassembled and installed without the use of complex tools and equipment. This not only reduces the labor intensity of the staff, but also improves work efficiency.

Therefore, the internal mesh structure of the rigid tubular mesh protective tube is the key to its excellent protection performance. This design not only ensures the durability of the protective tube and the ability to disperse impact force, but also provides multiple functions such as leakage prevention, pollution prevention and reduced fluid resistance. At the same time, the detachability of the mesh structure also brings great convenience to maintenance and replacement. With the continuous advancement of technology and the continuous development of the industrial field, it is believed that the rigid tubular mesh protective tube will play a more important role in the future.

WhatsApp:+8613626888261

WhatsApp:+8613626888261