Cable guardrails are divided into impregnated type (ord […]

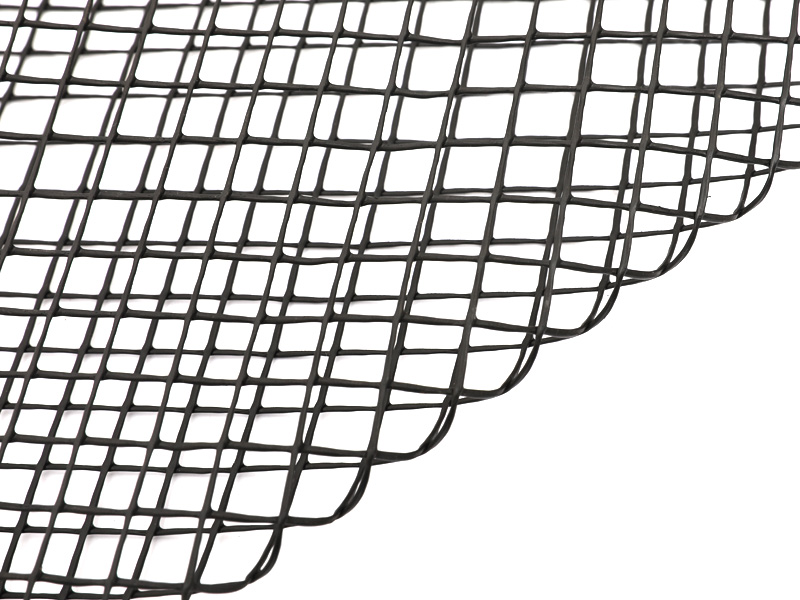

Cable guardrails are divided into impregnated type (ordinary type), impregnated type (enhanced type), hot-dip galvanized type (ordinary type), and hot-dip galvanized type (enhanced type). Class A uses 6 cables, Class B uses 5 cables, and the initial tension of Class A and B cables is 201d. The cables are 3x7 galvanized/right-twisted structure, with high strength and corrosion resistance.

Strong adaptability: In places with long straight sections and beautiful scenery, the cable guardrail has a beautiful appearance, the cable guardrail is more coordinated with the landscape, the crew has no sense of depression, and the driving is more comfortable. In snowy areas, installing cable guardrails can greatly reduce the workload of snow removal and improve wind and snow weather. the ability to do so.

Good safety: The cable guardrail has good flexibility, can effectively absorb the energy of the out-of-control vehicle, and is not easy to rebound for two accidents. Therefore, the vehicle damage and casualty rates are lower than those of concrete guardrails and beam guardrails. At the same time, the breakage rate of the cable guardrail is also lower than that of the wave guardrail.

Convenient construction: The spacing between the steel wire rope guardrail posts is flexible. When setting, it is easy to cross obstacles and adjust the pile position, which brings great convenience to construction and installation, and it is easy to adjust the line shape after the cable is hung.

Maintenance and repairs are simple: cable guardrails rely solely on the tension of the cables to withstand vehicle impacts, and rely on the disintegration and displacement of posts, brackets, and the friction of the cables to absorb the energy of runaway vehicles. Because cables work within the elastic range, struts and brackets often need to be replaced after an accident so that traffic can be quickly restored without replacing cables.

WhatsApp:+8613626888261

WhatsApp:+8613626888261